151st ASA Meeting, Providence, RI

Keeping in Contact: When Good Sockets Go Bad

Elizabeth Blickley - eab223@psu.edu

Popular version of paper 4pEA7

Old homes have a wonderful history, interesting character, and an inconvenient tendency for plugs to slip out of wall sockets while a hair dryer or vacuum is being used. As an electrical socket ages, it wears out and tends to lose its grip on a plug. This may be just a nuisance with household appliances, but for industrial cable connector assemblies (Figure 1), a plug falling out of a socket may cause injuries, costly outages, and environmental damage. This catastrophic failure can be avoided by periodically taking measurements to determine how well the socket is holding the plug. Sockets with weak contact forces can be replaced while sockets with strong contact forces can continue to be used. The aim of this research is to design a hand-held ultrasonic force sensor to measure the socket contact force.

The ultrasonic force sensor works by inserting a special tube into the socket. The tube is made of a material called lead zirconium titanate, or PZT, which is type of piezoelectric crystal. In a piezoelectric material, electrical and mechanical properties are linked together. So, when a piece of PZT is squeezed, it produces a voltage. As the piezoelectric tube is inserted into the socket, the socket grips the tube by applying a force to the outside of the tube. Since the electrical and mechanical properties of the piezoelectric tube are related, this mechanical force causes a change in electrical resonance frequency. Resonance occurs when the applied frequency equals the natural frequency of the material. The electrical resonance frequency can be measured using a network analyzer, an electronic testing device which provides information about the properties of electrical networks. The applied force and change in resonance frequency are directly proportional, so as the force on the outside of the tube increases, the change in electrical resonance frequency also increases. Therefore, the piezoelectric resonator can effectively be used as a force sensor by measuring the change in resonance frequency and relating it to the value of the applied force in order to calculate the sockets grip on the plug. Figure 2 shows the results of inserting a set of tubes into a set of sockets and recording the change in resonance frequency. By examining the data, it can be concluded that sockets 1 and 4 are in good condition, while sockets 2, 5, and 6 need to be replaced. These results are both sensitive as well as reproducible for a variety of tubes and sockets.

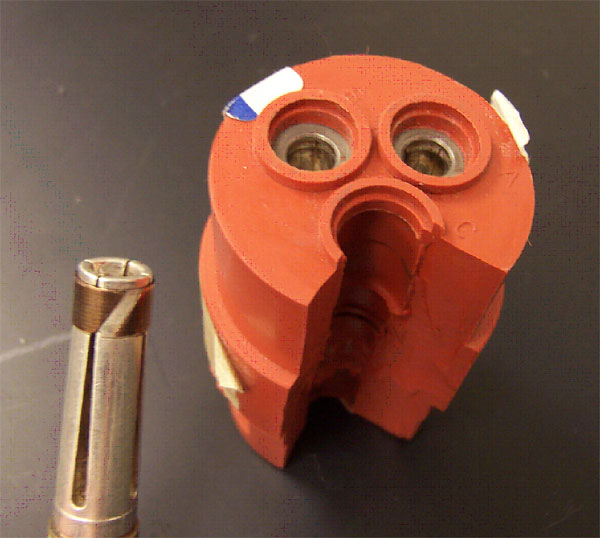

A tube holder (Figure 3) was designed and fabricated in order to make the socket testing process easier. This research can be used to develop portable, durable, and user-friendly socket testing equipment to calculate the socket contact force in a cable connector assembly.

|